Scientists Create New Power Source For Electric Cars Using Cobalt And Water Is The Only By-Product

University of Massachusetts Lowell has come up with a technique to produce hydrogen on demand. The process uses cobalt metal particles with surface nanostructures measuring billionths of a meter in size. This produces hydrogen at relatively low temperature and pressure to produce electricity. The hydrogen can then be used in a hydrogen fuel cell with up to 85% efficiency to power the EV.

With the dawn of the electric vehicle (EV) era, several battery technologies are being worked upon to be a potential fit to many standing issues, like the long recharging times for the most prevalent - lithium ion batteries. One such solution now comes from the University of Massachusetts Lowell and it uses only water, carbon dioxide and cobalt metal particles.

Researchers at the University have come up with a technique to produce hydrogen on demand which can be further used to power EVs. The process uses cobalt metal particles with surface nanostructures measuring billionths of a meter in size, to produce hydrogen at relatively low temperature and pressure.

Though this sounds similar to any other Hydrogen fuel cell, the highlighting difference is the use of cobalt in this technique, which converts from cobalt metal to cobalt oxide during the reaction and hence produces hydrogen and carbon dioxide. The hydrogen can then be used in a hydrogen fuel cell with up to 85% efficiency to power the EV. So essentially, the technique is a prelim to a hydrogen fuel cell. It produces hydrogen as the end product, which is then needed by the hydrogen fuel cell to produce electricity.

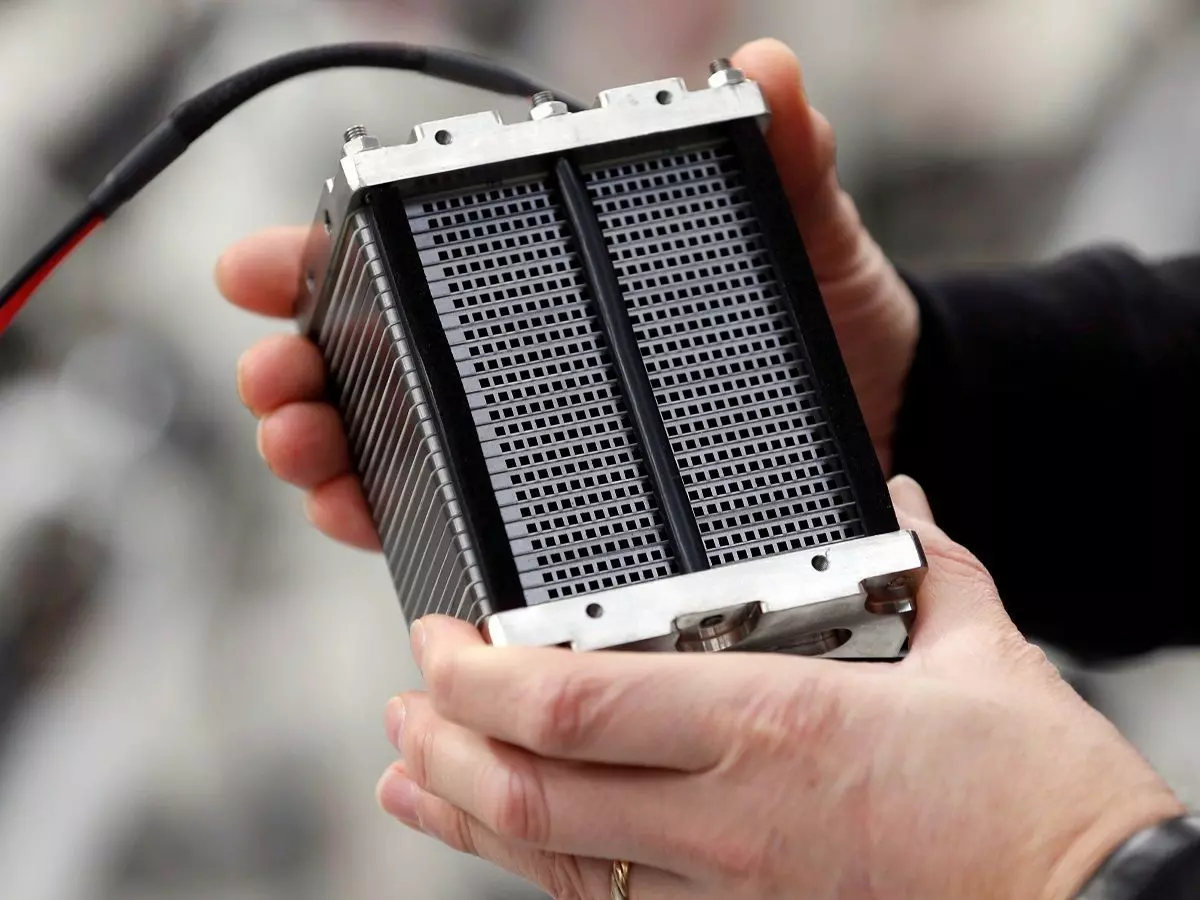

Representative Image: Reuters

Also read: Nathalie Is A Methane Powered Car That Recharges In 3 Minutes Flat, But Is It A Practical Car?

David K. Ryan, the project's principal investigator explains the setup as a stainless steel canister filled with cobalt. Through this canister, a carbonate solution of water and carbon dioxide is pumped and then heated up to 150 degrees. It is also subjected to a pressure of three atmospheres, around the same as in a car¡¯s tire.

Notably, the carbonate does not change or get consumed during the course of the reaction. Once the Hydrogen is produced, it can go directly to a hydrogen fuel cell where it can be mixed with oxygen to produce electricity and water. Even the produced water can then be looped back into the canister for the catalytic solution.

As can be understood from the working, the canister would require a pump, a heater and a compressor. As per the team of researchers, the electricity produced by the hydrogen fuel cell will be enough to power all three of the components, in addition to the car¡¯s electric motors.

Representative Image: Reuters

Ryan says that hydrogen with up to 95% purity can be produced through this procedure. What is even more appealing about the technique is that it eliminates the need to transport or store hydrogen for the hydrogen fuel cells. This effectively nullifies the corresponding risks associated with carrying the highly flammable gas. Here, you only produce it when you need it.

The effective range of the canister has been said to be anywhere between 300 to 400 miles (482 - 643 kms), meaning one can simply swap the canister after the mentioned duration. The researchers say that even the cobalt in the used up canister can be regenerated using renewable energy sources such as wind or solar.