India To Offer $1 Billion Reward To Every Chip-Maker Who 'Makes In India¡¯

Semiconductors are facing an unprecedented global shortage thanks to the explosion in demand during the Covid-19 pandemic. India is reportedly planning to offer more than $1 billion in cash to each semiconductor company that sets up manufacturing units in the country.

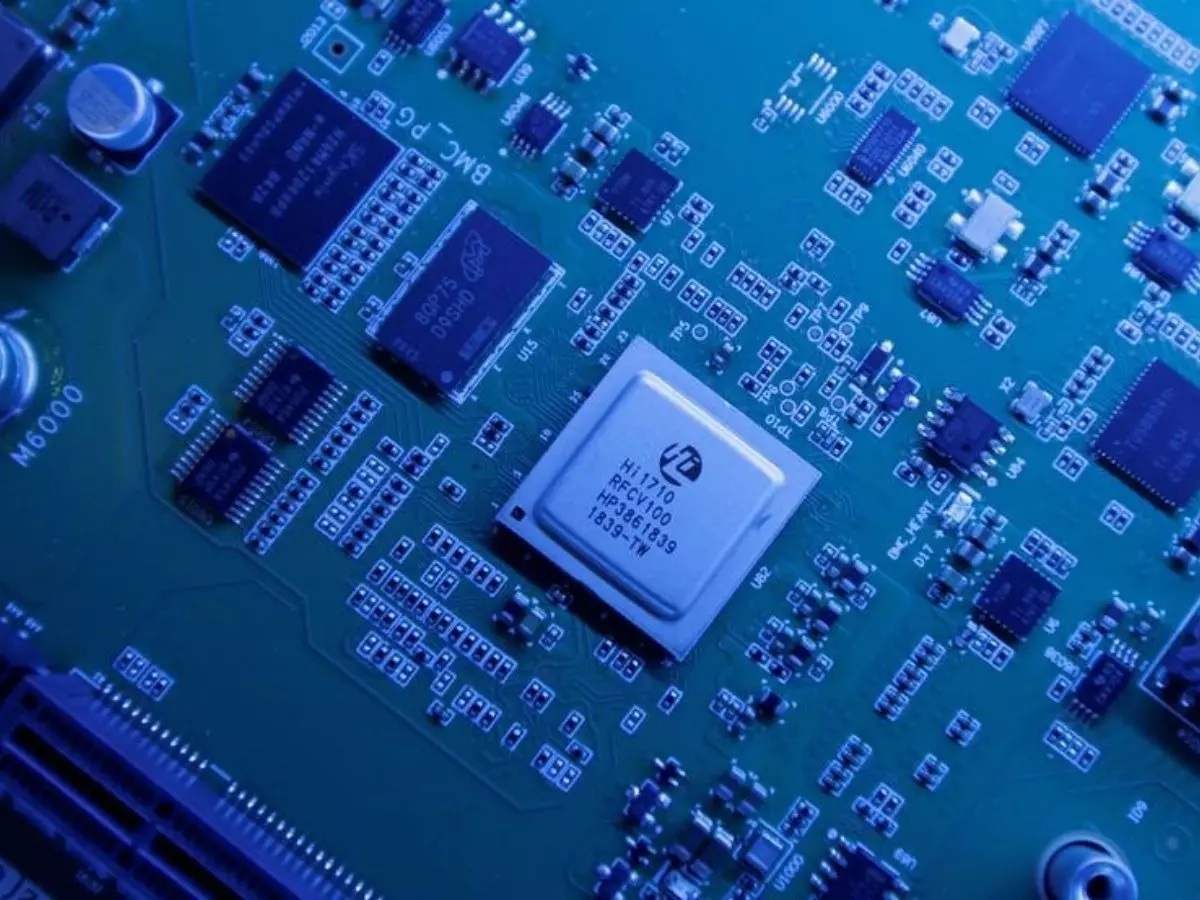

From cars and microwave ovens to computers and smartphones you¡¯re reading this piece on--inside every one of them are tiny unseen pieces of tech called microprocessors or chips that make it all possible.

These are your typical silicon chips that are basic building blocks of modern computation and the most crucial and expensive component inside your gadgets.

Getty Images

Getty Images

But semiconductors are facing an unprecedented global shortage, thanks to the explosion in demand during the Covid-19 pandemic. And that has set the alarm bells ringing. So much so that car manufacturers such as Ford, Nissan, Volkswagen, Fiat Chrysler and Toyota had to cut back production. And with companies panic buying chips to shore up stocks, the shortage has increased the prices of final products.

India¡¯s billion dollar cash incentive

And to fill that manufacturing void of electronic products, India is reportedly planning to offer more than $1 billion in cash to each semiconductor company that sets up manufacturing units in the country.

ALSO READ: How IBM India Designed A 7nm Enterprise Chip, And Why It's Good For Indian Innovation

A senior government official told Reuters that the government as well as private companies will mandatorily procure ¡®made in India¡¯ chips so that the new fabrication units have assured buyers for their product.

Reuters

Reuters

India is currently the world¡¯s second-biggest mobile manufacturer after China and looks to establish reliable suppliers for its electronics and telecom industry, especially after the military and diplomatic standoff with Beijing last year.

Intel (US), Samsung (South Korea) and TSMC (Taiwan) are The Big Three chip manufacturers. While the former two can design, manufacture and sell chips from end to end, TSMC is the undisputed leader, in terms of sheer scale, sophistication and reach, accounting for more than half the total market share of foundry business.

India's attempts to woo semiconductor companies

This is not the first time India has expressed interest in luring chipmakers to ¡®Make in India¡¯. However, its previous attempt to set up two new $5 billion chip plants were deterred by India's wobbly infrastructure, unstable power supply and poor planning.

Reuters

Reuters

More recently in December last year, the government invited an ¡°Expression of Interest¡± from chipmakers for setting up or expanding existing Semiconductor wafer as well as device fabrication facilities in India or acquisition of Semiconductor fabrication facilities outside the country.

Government of India invites EoI from companies/ consortia desirous of setting up / expansion of existing Semiconductor wafer / device fabrication (FAB) facilities in India or acquisition of Semiconductor FABs outside India @GoI_MeitY @NITIAayog https://t.co/uugqLiqjE8

¡ª Electronics India (@Electronics_GoI) December 15, 2020

According to the consulting firm McKinsey, it costs at least $5.4 billion to build a facility with the latest 5-nanometre production lines. Reuters said that it would take 2-3 years to set up a chip fabrication unit after all the approvals are in place.