Like Black Panther Suit, Scientists Print Wearable Sensors Into Human Skin

Wearable sensors have taken different shapes and forms over the years with the advancements in science enabling them. A new research now takes them to the next evolutionary step printing such sensors directly onto the human body. Not unlike the host of sensors found on the suit of the Marvel superhero Black Panther an international team of scientists has printed sensors directly on human skin. This is because the bonding process for the metallic ...Read More

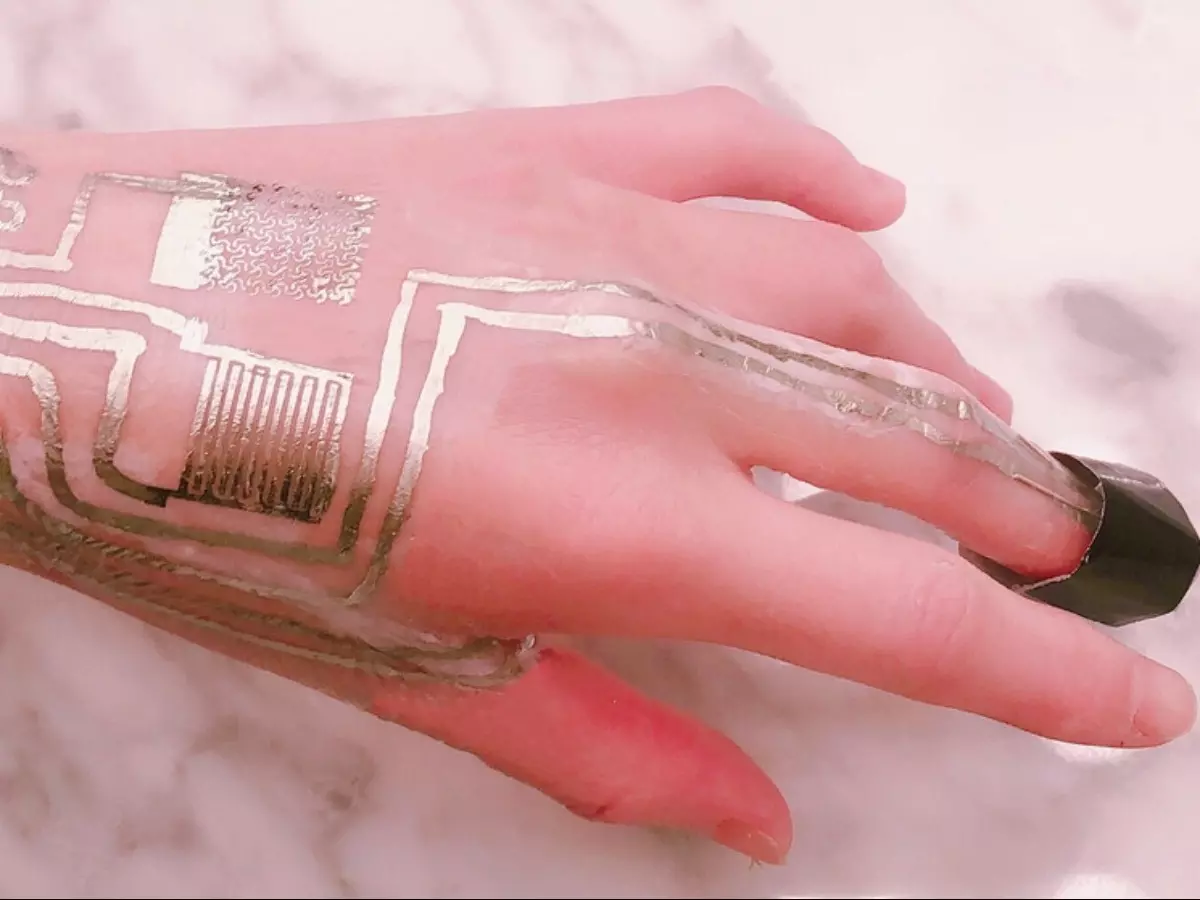

Wearable sensors have taken different shapes and forms over the years with the advancements in science enabling them. A new research now takes them to the next evolutionary step, printing such sensors directly onto the human body.

(Image: Penn State University)

(Image: Penn State University)

Not unlike the host of sensors found on the suit of the Marvel superhero Black Panther, an international team of scientists has printed sensors directly on human skin. While the task in itself was not unimagined, the researchers managed to add an interesting twist to it - they did it without the use of heat.

Led by Huanyu ¡°Larry¡± Cheng, Dorothy Quiggle Career Development Professor in the Penn State Department of Engineering Science and Mechanics, the study has now been published in ACS Applied Materials & Interfaces. The study focused on implementing health monitoring techniques through wearable circuits, directly onto the human skin.

¡°In this article, we report a simple yet universally applicable fabrication technique with the use of a novel sintering aid layer to enable direct printing for on-body sensors,¡± said first author Ling Zhang, a researcher in the Harbin Institute of Technology in China and in Cheng¡¯s laboratory.

The major breakthrough

Such wearable sensors are not unthought-of before. In fact, Cheng and his colleagues had previously developed flexible printed circuit boards to be used in such wearable sensors. The challenge, however, was to print them directly onto the human skin.

This is because the bonding process for the metallic components in the sensor, known as sintering, typically requires temperatures of around 300 degrees Celsius. As can be understood, the human skin is not able to endure such high temperatures.

So to bond the sensor¡¯s silver nanoparticles together, the scientists added a nanoparticle to the mix, bringing the sintering temperature to about 100 C. ¡°But it¡¯s still higher than we can stand at skin temperature,¡± Cheng said, who noted that about 104 F (40 C) could still burn skin tissue.

¡°We changed the formula of the aid layer, changed the printing material and found that we could sinter at room temperature,¡± revealed Cheng in a University release.

For this, the researchers used polyvinyl alcohol paste ¡ª the main ingredient in peelable face masks ¡ª and calcium carbonate ¡ª which comprises eggshells, as the sintering aid layer.

¡°The outcome is profound,¡± Cheng said. ¡°We don¡¯t need to rely on heat to sinter.¡±

Sensors on the body

(Image: ACS Applied Materials & Interfaces)

(Image: ACS Applied Materials & Interfaces)

Once patched, the sensors are capable of ¡°precisely and continuously¡± capturing temperature, humidity, blood oxygen levels and heart performance signals, says Cheng. The researchers further linked the on-body sensors with a wireless network to monitor the combination of signals developed from the sensors.

Cheng points out that the process is also environmentally friendly. The sensor remains durable in tepid water for a few days, but will be removed easily in a hot shower.

¡°It could be recycled, since removal doesn¡¯t damage the device,¡± Cheng said. ¡°And, importantly, removal doesn¡¯t damage the skin, either. That¡¯s especially important for people with sensitive skin, like the elderly and babies. The device can be useful without being an extra burden to the person using it or to the environment.¡±

In further research, the scientists plan to tweak the technology to target specific applications. One of these applications can even be a precise on-body sensor network to monitor the particular symptoms associated with COVID-19.