New Face Mask Material Better Protects Against Virus, Is Biodegradable To Reduce Waste

Most of the use and throw masks are made from synthetic materials that are often not biodegradable. The use and throw masks only end up getting thrown in a garbage dump where it rots for years, affecting the environment. However, researchers have now created a new mask material that is not only capable of removing virus-sized nanoparticles but is also biodegradable.

Today, COVID-19 has forced us to not even think of leaving our homes without face masks. The demand has surged uncontrollably, resulting in grave shortage for medical staff -- people who truly need it the most -- across the globe.

Reuters

Reuters

Most of the use and throw masks are made from synthetic materials that are often not biodegradable. The use and throw masks only end up getting thrown in a garbage dump where it rots for years, affecting the environment.

However, researchers have now created a new mask material that is not only capable of removing virus-sized nanoparticles but is also biodegradable.

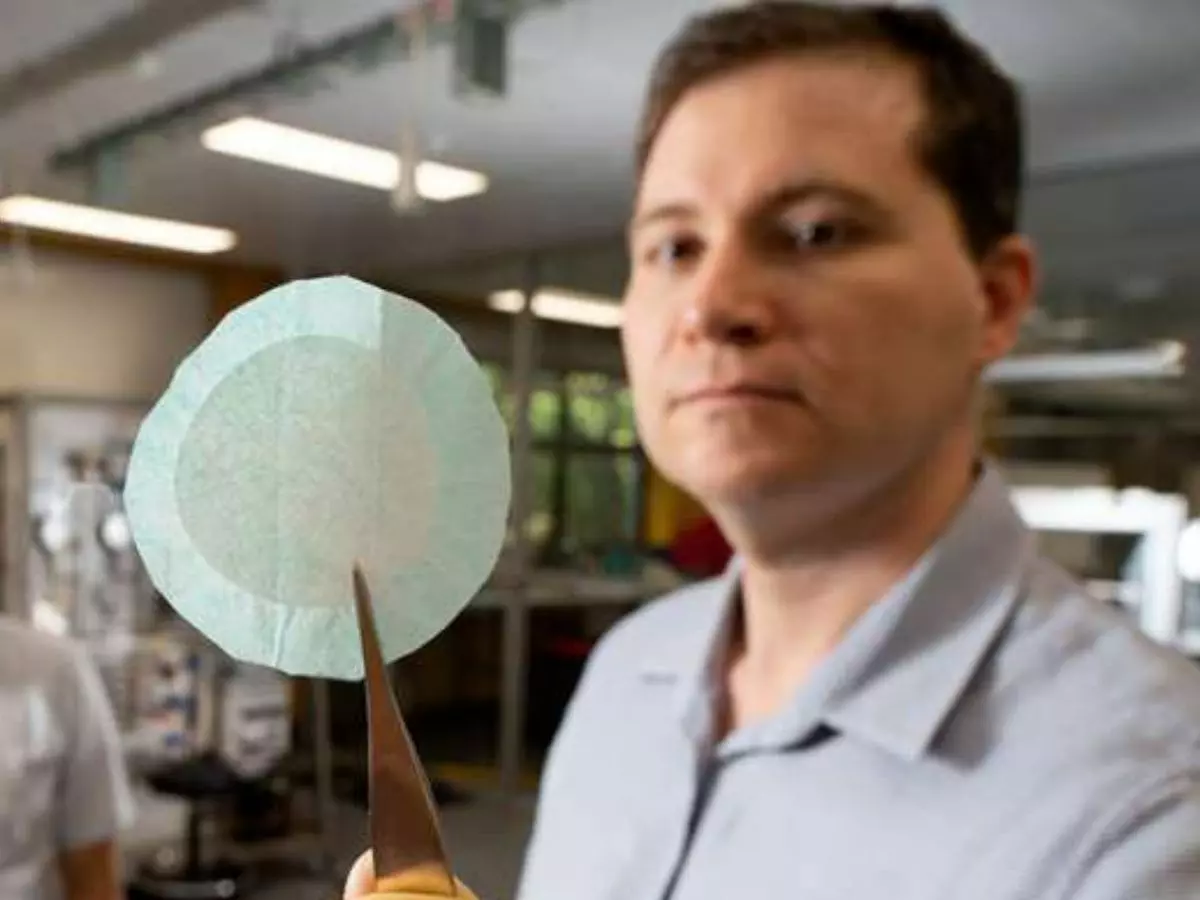

Reported first by Phys.org, The development is done by the Queensland University of Technology process engineer Dr Thomas Rainey and his research team. He said in a statement, "We have developed and tested a highly breathable nanocellulose material that can remove particles smaller than 100 nanometers, the size of viruses."

QUT

QUT

He further added, "I see many people wearing masks which are not tested for viruses. We have tested this material thoroughly and found it to be more efficient in its ability to remove virus-size nanoparticles than the high-quality commercially available masks we tested and compared it with.

They¡¯ve created a new material that offers better breathability while improving protection from viruses. The new material adds comfort while eliminating fatigue that people normally experience while wearing respiratory masks.

He said, "Our tests showed the new material was more breathable than commercial face masks, including surgical masks. This new material has excellent breathability, and a greater ability to remove the smallest particles."

QUT

QUT

The mask filters are made from waste plant material like sugar cane bagasse, and other agricultural waste products, thus making it completely biodegradable. Moreover, manufacturing isn¡¯t expensive.

Researchers have established a proof of concept as a nanoparticulate filtration material and are currently on a lookout for industry partners.