This 3D-Printed Foam Could Cut Cement's 7% Of All Global Carbon Emissions

Cement is the single biggest emitter of carbon dioxide on the planet. Engineers at ETH Zurich took note of the problem at hand and developed 3D-printed formwork elements to create pre-cast concrete slabs

Researches are now employing the wonders of 3D printing to cut down usage of concrete with a one-track mind to reduce the carbon footprint associated with traditional ways to use concrete.

Cement is the single biggest emitter of carbon dioxide on the planet. Engineers at ETH Zurich took note of the problem at hand and developed 3D-printed formwork elements to create pre-cast concrete slabs.

Dezeen

Dezeen

How FoamWork works

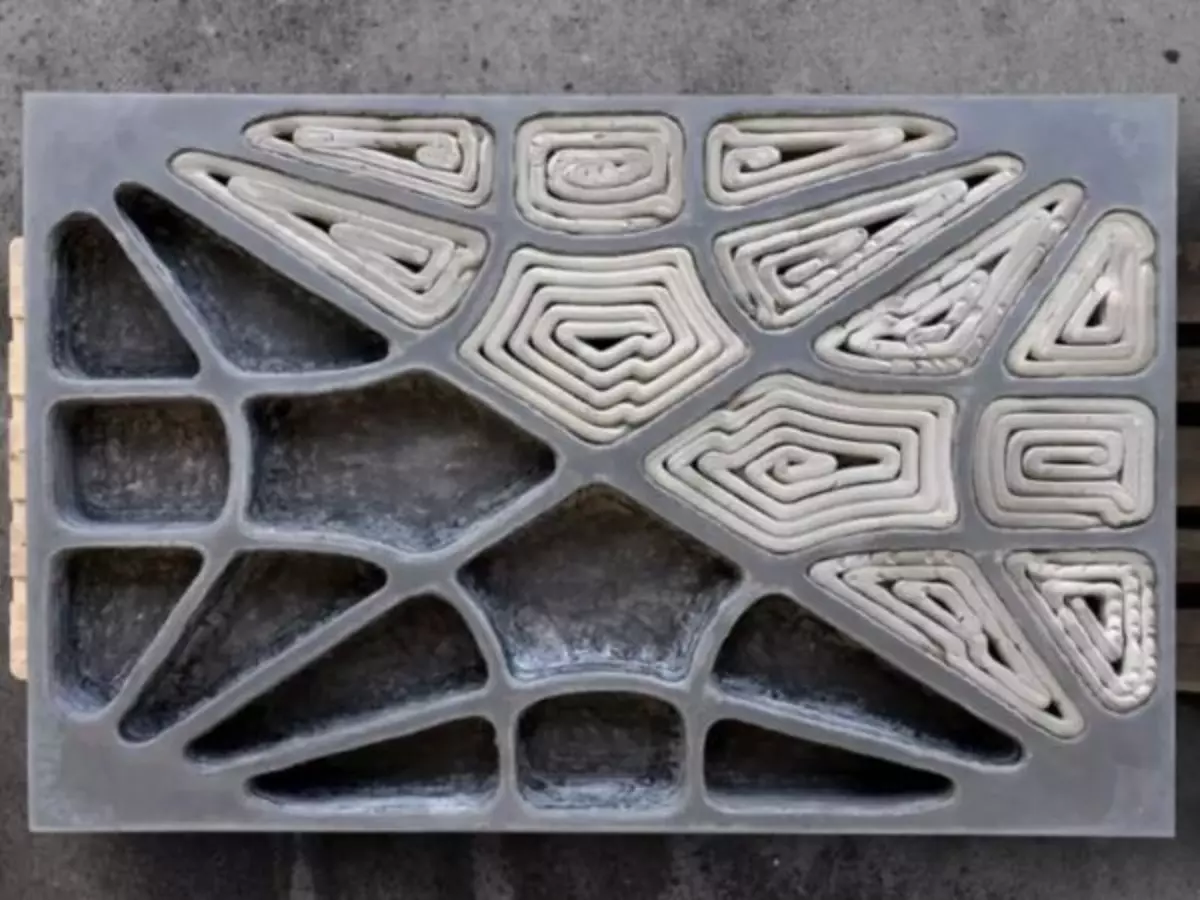

Called "FoamWork", the system uses a traditional rectangular mould filled with 24 regular mineral formwork elements in various shapes and sizes. Then, the concrete is cast around them and left to cure, Dezeen reported. This creates hollow cells through the panels.

Its primary architect Patrick Bedarf believes that will mass scaling, it could help reduce the carbon footprint of construction and cement which alone is responsible for 7% of all global emissions.

The fact that the concrete slab created by ETH Zurich using 3D printing has lower mass would also cut down on efforts required to ship and handle the concrete at construction sites.

Also read: This Is World¡¯s First 3D Printed Vegan Burger Made In Just 6 Minutes

What about emissions? To cut down on emissions associated with regular cement, FoamWork uses "fly ash" - made up of waste products from coal-fired power stations. A Swiss startup called FenX helps them with the same.

In addition, the final product by FoamWork may be left in place to improve the insulation of the precast concrete slab or be recycled and reprinted to generate new formwork. The entire process also has the potential to be zero-waste, for no offcuts are generated in the manufacturing process.

Dezeen

Dezeen

Also read: Humanity's Closer To 3D Printing Full Organs For Transplants And Save Lives

The Global Cement and Concrete Association recently announced that it hopes to reach net-zero emissions by 2050 and FoamWork might be one of the many solutions they may be able to use.

What do you think about using 3D-printed materials to reduce carbon footprint caused by cement? Let us know in the comments below. For more in the world of technology and science, keep reading Indiatimes.com.

References

Hahn, J. (2022, January 10). ETH Zurich develops formwork from 3D-printed foam to slash concrete use in buildings. Dezeen.

How can we cut the emissions from concrete use? (2022, January 13). World Economic Forum.