New Material Inspired From Camel Keeps Perishable Food Cool Without Electricity

A camel's fur has several benefits to help the animal survive extreme temperatures -- hot or cold. Moreover, research has shown that a shaved camel loses 50 percent more moisture than an unshaved one. Looking at this, MIT developed the two-layered material where the bottom layer is essentially a substitute for sweat glands, made using hydrogel.

If there is one piece of the appliance at home that we truly cannot work without, it's the refrigerator. It helps keep our food fresh for longer and helps us avoid unnecessary wastage.

And refrigerators come in all shapes and sizes. But they're also very power hungry and not very portable.

Unsplash

Unsplash

However, researchers at MIT have developed a new material that would enable keeping perishable goods cold without needing any sort of refrigeration. The material includes a two-layer passive cooling system made of hydrogel and aerogel that keeps things cool without the need for electricity. And the inspiration for this new material has come from the mighty ship of the desert.

A camel's fur has several benefits to help the animal survive extreme temperatures -- hot or cold. Moreover, research has shown that a shaved camel loses 50 percent more moisture than an unshaved one.

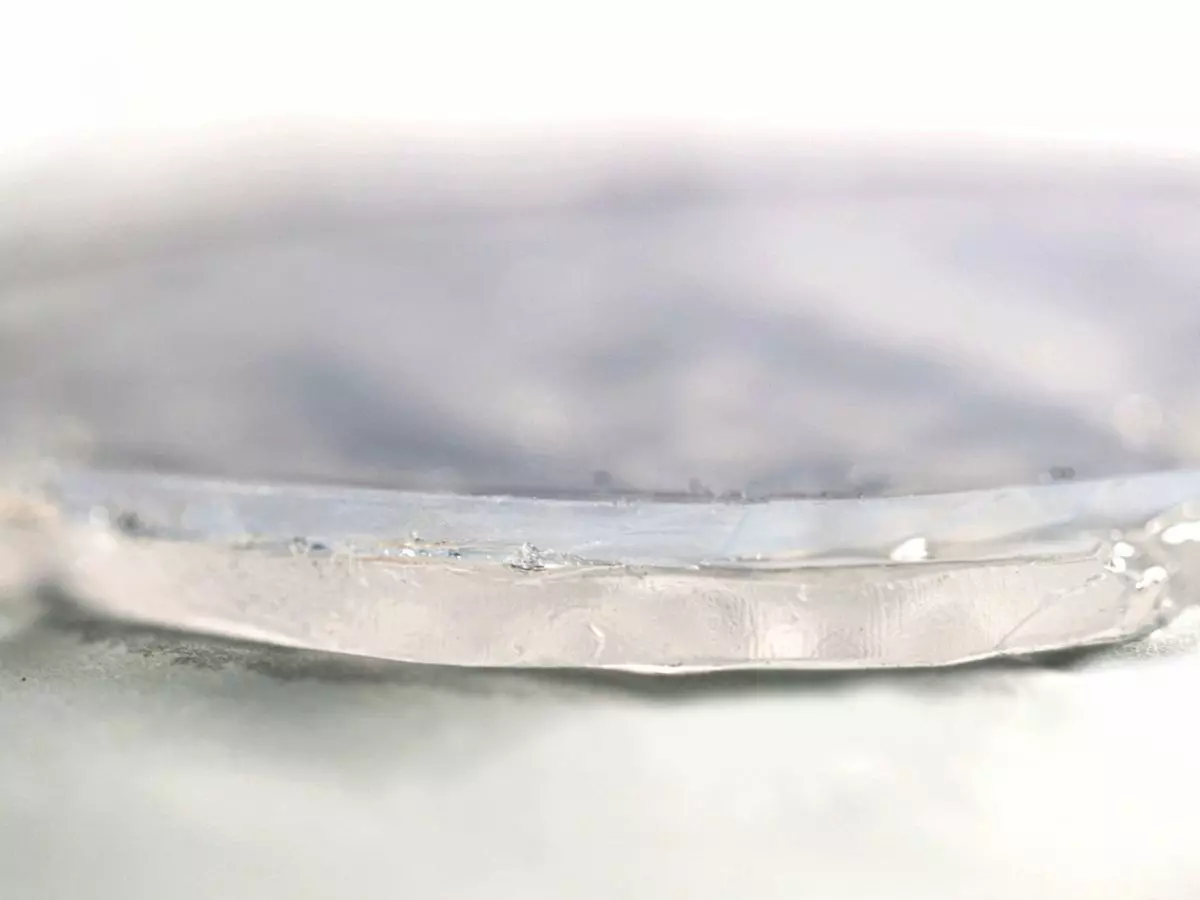

Looking at this, MIT developed the two-layered material where the bottom layer is essentially a substitute for sweat glands, made using hydrogel. The upper layer is an aerogel layer that acts like the camel's fur, separating the heat outside while keeping the insides cold.

MIT, in its testing, has found that this two-layered material can offer cooling of over seven degrees celsius, five times longer than hydrogel alone, while also being less than half an inch thick. Basically, the material can carry on the cooling for more than eight days, compared to only two days with current materials.

MIT

MIT

Researchers feel a system like this could come in handy for easily perishable food items like meat, fish etc. It can also enable the delivery of vaccines in locations that are hard to reach, without worrying about them going back due to warm temperatures.

As of now, the only challenge that remains is that of the processing equipment to manufacture aerogel. The equipment is not only space-consuming but it is also an expensive process. However, researchers believe that the process could get more cost-effective once it is produced on a larger scale.