Explained: How The Shortage Of Semiconductor Chips Is Going To Affect Us

The Covid-19 pandemic-induced lockdown added the shortage of semiconductor chips in the global market. When disruptions of supply worsen the condition, countries including the United States and India brought the policies to meet the demand.

The Covid-19 pandemic-induced lockdown added the shortage of semiconductor chips in the global market. When disruptions of supply worsen the condition, countries including the United States and India brought the policies to meet the demand.

The shortage will directly hit the pockets of consumers and electronic items that we use in our day to day lives may see increased prices. What are semiconductor- chips that could affect the entire electronic/technology-driven space?

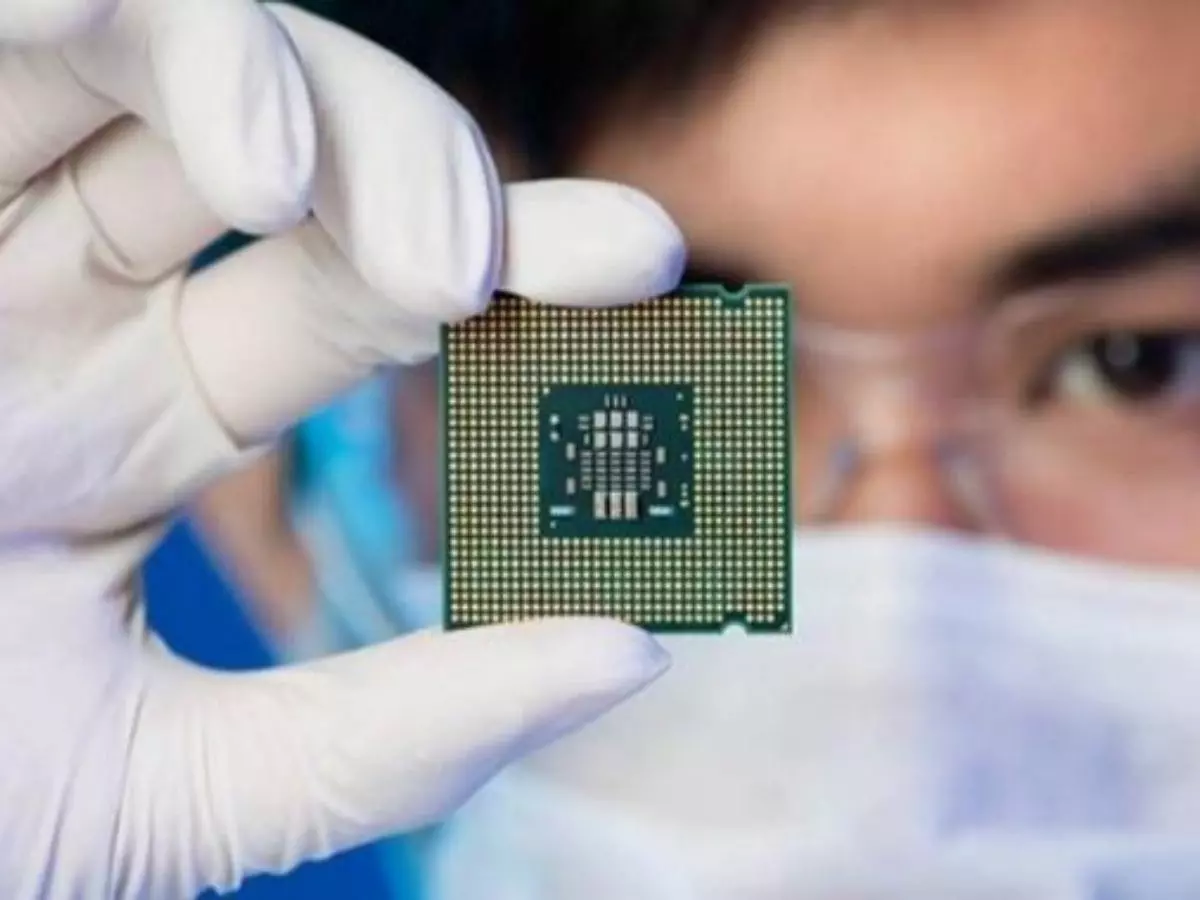

What are Semiconductor Chips?

Unsplash

Unsplash

Simply put, they are the prominent component that powers electronic items that exist in your surroundings. Usually made of silicon, the electricity can be controlled using semiconductor chips in various electronic items like our cars, laptops, smartphones, refrigerators etc.

Technically, Semiconductors (chips) are materials which have conductivity between conductors and insulators. Semiconductor materials include pure elements and compounds like silicon, germanium, gallium, and arsenide or cadmium selenide.

Why semiconductor chips are crucial?

Unsplash

Unsplash

These chips play a crucial part in the functioning of all modern electronics and information and communications technology products. In simple terms, they can be considered as basic building block parts of contemporary automobiles, household gadgets and essential medical devices such as ECG machines.

The Covid-19 pandemic exceeded the demand for these chips as online activities increased worldwide. With a new set-up where people started spending their most of time on online activities, working from home, the market demand for chip-powered computers and smartphones was inundated the supply chain. The time highlighted the rising need for semiconductor chips.

However, pandemic led lockdown forced to shut various economic activities including the chip-making facilities in several countries like South Korea, Japan, the US and China. The shortage of chips was already in the market and a famine-like picture emerged later.

Taiwan leads the manufacturing of chips

unsplash

unsplash

Having 56% of the foundry business of manufacturing chips, Taiwan Semiconductor Manufacturing Corporation (TSMC) is the world¡¯s largest contract chipmaker. Big brands like Qualcomm, Nivdia and Apple are its customer. South Korea and China are also big contributors to meet the global demand.

Manufacturing Semiconductor-chips is not easy!

Acknowledging high demand, it is not easy to ramp up the manufacturing of chips on short notice as it requires time to set up chip foundries. It is a difficult, expensive and time-consuming process.

A report published in Bloomberg quint tells "Manufacturing a chip typically takes more than three months and involves giant factories, dust-free rooms, multi-million-dollar machines, molten tin and lasers.¡±

unsplash

unsplash

According to a report published in Outlook India, several companies, namely, Intel, Samsung and Taiwan Semiconductor Manufacturing Company (TSMC) have announced new chip fabrication plants but the process itself takes years to be completed.

Who will be affected by the shortage?

The consumers will be directly affected by this shortage as increased demand will result in soaring prices of electronic devices.

A report published in Indian Express indicates that giant companies like Apple and Samsung had begun stockpiling them. Apple was hit by 20% dip in the quantity produced in September-October last year as faced issues with the production of iPhone 13.

One aspect that emerged out of the report is that even if stockpiling saves smartphones availability but automobile industry might face serious problems. They already are surviving an economic slowdown.

What are the solutions?

According to a report (May, 2021) published by Gartner estimates that the chip shortage could continue till the second quarter of 2022 across categories of devices.

File Photo

File Photo

Many CEOs and companies predicted that this shortage could last in the coming two years. However, opinions are varied as a Chinese automotive industry group said that the worst of the global car chip shortage is over.

Last year in August, Electric vehicles (EV) maker Tesla announced the project of developing a "Dojo" chip to train artificial intelligence networks in data centres.

Initiatives by India to tackle the issue

Reuters

Reuters

The shortage appears to be an apparent challenge but also emerges an opportunity for countries like India. Recognising the fact, the Union cabinet allocated Rs 76,000 crore to support the development of a ¡®semiconductors and display manufacturing ecosystem¡¯.

India Semiconductor Mission and Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS) have also been launched by the Indian government.

However, some of the challenges with these schemes are requirement of high investment, minimal fiscal support from the government, insufficient PLI scheme grants and lack of fab capacities, resources etc.

For more on news and current affairs from around the world please visit Indiatimes News.